总部地址 北京市怀柔区乐园大街9号 邮编:101407

自驾车路线:上京承高速,在15号出口下高速至杨雁路一直向北行驶,中高路右拐即到伊特克斯公司

乘车路线:在东直门汽车站乘坐866路(东直门至雁栖开发区)公交车,至乐园大街北口站下车。

客户服务热线:400-086-8156 传 真:010-80703923 总 机:010-61702399 , 61702398 客户服务邮箱: sales@etelux.com 海外业务中心联系方式 电话:0086-10-56708156 邮箱:international@etelux.com | 伊特克斯电池智能装备 柱状及软包电池智能制造装备 客户服务热线:400-086-8156 传真:010-80703923 手机:13910659652 |

分支机构联系方式 为了给用户提供全面、及时的售前、售后服务,伊特克斯在销售、服务网络覆盖全国。

伊特克斯在国内不设代理商,所有分支机构均属于我公司直接下属机构。办事处详细情况请咨询服务热线 400-086-8156

|

全国联系方式: |

||

|

华北一区(北京、天津、河北) |

李经理:13918180432 |

邮箱:liminghua@etelux.com |

|

华北二区(北京) |

王经理:13811584392 |

邮箱:wangbaoqiang@etelux.com |

|

华北三区(黑龙江、哈尔滨、长春) |

姜经理:13811779217 |

邮箱:changchun@etelux.com |

|

华北四区(北京、山西、内蒙) |

吴经理:15699752338 |

邮箱:wudagang@etelux.com |

|

华中区(河南、湖南、湖北、江西) |

占经理:13910449037 |

邮箱:wuhan@etelux.com |

|

华东区(上海、江苏、山东、浙江、福建、安徽) |

郭经理:13918771991 |

邮箱:shanghai@etelux.com |

|

华南区(广东、深圳、广西、海南) |

区经理:18613800921 |

邮箱:guangzhou@etelux.com |

|

西南区(四川、云南、贵州、重庆) |

杨经理:13811775273 |

邮箱:chongqing@etelux.com |

|

西北区(陕西、宁夏、甘肃、青海、新疆) |

李经理:13910659652 |

邮箱:xian@etelux.com |

| 伊特克斯"365无忧";--超值延保服务 |

| “365无忧”延保服务价值 延保服务价值 全天候 全过程 更省钱 更及时 更安心 更方便 维修费用可控 专业维护服务 |

| ★ 全天候: 一年365天为用户提供服务。 |

| ★ 全过程: 一站式维修、保养、培训服务,建立完整的用户档案。 |

| ★ 更省钱: 1)购买延保服务后,设备维修时您无需支付任何额外费用(耗材除外); 2)免费增值服务,适时更换您平时不注意报修的零部件,消除隐患,保证设备一直处于良好使用状态; 3)更优惠的硬件升级,以满足您对设备更高的需求; 4)更优惠购买耗材。 |

| ★ 更及时: 您选择延保服务后,公司就能在工程师那里备置常用模块化配件,工程师可以高效及时地更换出现故障的模块,缩短维修周期,使您的生产工作更顺畅、更高效,为您创造更高的利润。 |

| ★ 更安心: 设备在过了1年的免费保修期后,将不再享受全免保修服务,而购买延保服务后,您可以继续享受免费保修,我们会定期回访设备使用情况,为您提供优质、完善的设备保修服务,免去您的后顾之忧。 |

| ★ 更方便: 您只需拨打伊特克斯统一客户服务热线:400-086-8156。400呼叫中心将24小时为您服务,您的一切需求我们能即刻满足。 |

| ★ 维修费用可控: 未购买延保服务,维修费用将根据故障设备和故障情况收取,企业对设备维修费用不可控;购买了延保服务,对维修费用就可控了,变为预算制投入,可大幅减少设备维修成本增加带来的风险。 |

| ★ 专业维护服务: 让我们的服务团队为您提供更多专业支持,携手共创美好未来! |

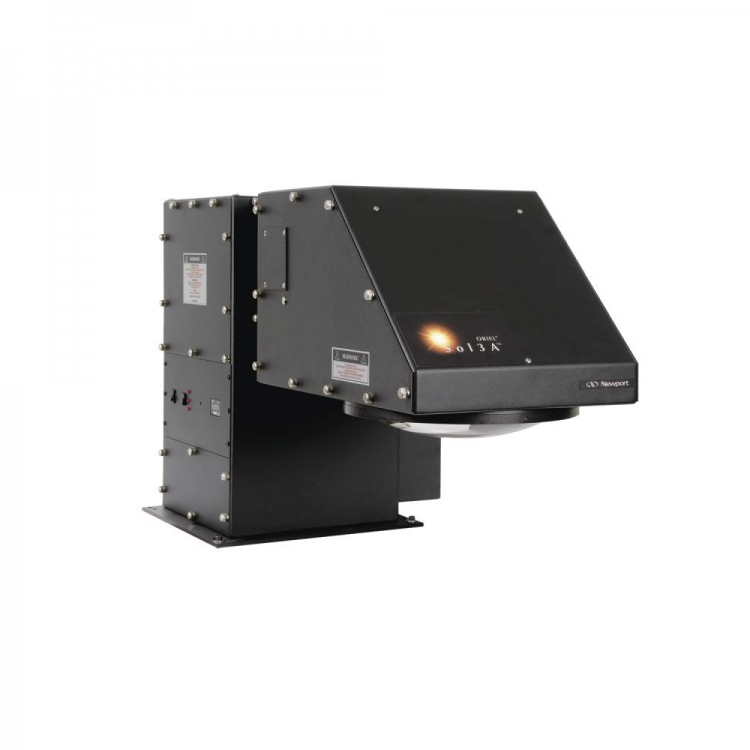

Sol3A Class AAA Solar Simulators 太阳光模拟器

Output beam sizes 2x2", 4x4”, 6x6” , 8x8", and 12 x 12"

Factory certified Class AAA CW systems

Calibration certificate validating Class AAA performance for all 3 standards: IEC, ASTM and JIS

Long-lived, highly reliable instruments designed specifically for 24/7 production environments

Easy lamp replacement

Non-reflective black finish reduces stray light

Temperature sensors and interlocks ensure operator safety

Leveraging over 40 years of experience in light source and power supply design, Newport’s Oriel® brand is proud to introduce the latest innovation in solar

simulators – the Oriel Sol3A™ Class AAA Solar Simulator family. The product family includes:

Model 94123A = 12 x 12 inch Beam Size

Model 94083A = 8 x 8 inch Beam Size

Model 94063A = 6 x 6 inch Beam Size

Model 94043A = 4 x 4 inch Beam Size

Model 94023A = 2 x 2 inch Beam Size

All Oriel Sol3A solar simulators are certified to IEC 60904-9 Edition 2 (2007), JIS C 8912, and ASTM E927-5 standards for Spectral Match, Non-Uniformity of

Irradiance, and Temporal Instability of Irradiance. By convention, Class AAA is reported with the first letter representing Spectral performance, the second

letter Uniformity of Irradiance, and the third letter Temporal Stability. The Oriel SOL 3A solar simulators all use a single lamp design to meet not one or two, but

all three performance criteria without compromising the 1 Sun output power, providing true Class AAA performance. The Oriel Sol3A uses a black non-

reflective finish to minimize stray light and incorporates captive screws for all panels requiring user access to facilitate lamp replacement, alignment, and filter

changes. Safety interlocks prevent inadvertent exposure to UV light. The Oriel Sol3A rugged design is backed by the Newport Corporation''s world wide

organization.

Why Class AAA?

Photovoltaic (PV) cell research and manufacturing are evolving at an amazing rate, with new technologies like thin film processes, tandem junction and multi-junction cells, organic thin films and dye sensitized cells all requiring careful evaluation of their performance. The old designation of “Class A” solar simulators had become standard in most test laboratories and manufacturing environments, but the definition of Class A has degraded to mean a system that is capable of meeting any one (typically spectral match) of the three performance parameters called out in the test methods. In October 2007 the IEC revised the method used to evaluate the performance of a solar simulator. The new standard calls for quantifying and reporting the performance of each of three performance criteria separately. A solar simulator is now measured as class A, B, or C for Spectral Match, Non-Uniformity of Irradiance, and Temporal Instability of Irradiance. The new Sol3A solar simulators have been designed to meet Class A performance for all 3 of the test requirements, Spectral Match, Non-Uniformity of Irradiance, and Temporal Instability of Irradiance as called out by IEC 60904-9 Edition 2 (2007) edition, JIS C 8912, and ASTM E 927-05.

By ensuring measurement uniformity that allows results comparability and traceability, Class AAA systems reduce binning variability of photovoltaic cell testing as compared to so called Class A, Class B or non-classified sources. This performance consistency allows for precise comparison of performance data for researchers engaged in developing novel solar materials.

Newport Corporation puts each Oriel Sol3A™ through rigorous testing for all 3 standards (IEC, STM, and JIS) to insure compliance and supplies a certificate of calibration for all three standards.

Defining Class AAA Performance Standards

Photovoltaic standards mandate that Class AAA solar simulators meet demanding requirements in three key performance areas: spectral match to the solar spectrum, spatial non-uniformity of irradiance, and temporal instability of irradiance.

There are three standards that define solar simulator performance.

IEC 60904-9 Edition 2 (2007) Photovoltaic Devices – Part 9: Solar Simulator Performance Requirements

JIS C 8912-1998, Solar Simulators for Crystalline Solar Cells and Modules

ASTM E 927-05 (2005) Specification for Solar Simulation for Terrestrial PV Testing

Table 1 Class AAA Standards and Specifications

| Organization | IEC | JIS | ASTM |

| Performance Parameter | 60904-9-2007 | C 8912 | E92-05 |

| Spectral Match (fraction of ideal percentage) | 0.75 - 1.25 | 0.75 - 1.25 | 0.75 - 1.25 |

| Non-Uniformity of Irradiance | 2.0% | 2% | |

| Temporal Instability | 0.5% STI | 2% | |

| |

Spectral Match

The standards define the spectral match of a solar simulator as a percentage of the integrated intensity in 6 spectral ranges (listed in Table 2). Any deviation from the specified percentages must then lie within a range that determines the class of the simulator. For Class AAA, this range is 0.75 to 1.25 times the ideal percentage.

Spectral Match

Table 2 Ideal Spectral Match Defined by IEC Standards

| Spectral Range (nm) | Total Irradiance Range (%) | Ideal % |

|---|---|---|

| 400 - 500 | 13.9 - 23.1 | 18.5 |

| 500 - 600 | 15.1 - 25.1 | 20.1 |

| 600 - 700 | 13.7 - 22.9 | 18.3 |

| 700 - 800 | 11.1 - 18.5 | 14.8 |

| 800 - 900 | 9.2 - 15.3 | 12.2 |

| 900 - 1100 | 12.1 - 20.1 | 16.1 |

Fig. 1 Oriel Sol3A Spectral Match with AM 1.5G

spectral correction filter meets IEC, JIS, ASTM Class A

requirements to for spectral match.

Spatial Uniformity of Irradiance

The irradiance uniformity over the work area is the most difficult Class AAA requirement to achieve and maintain. Hot spots can lead to significant errors in measured cell efficiency and can cause inaccurate binning of cells. The Class AAA spatial non-uniformity performance standard is designed to minimize the impact of hot spots and has a very stringent requirement of ≤2%. The plot below shows the uniformity of the irradiance across a typical simulator working area. Each unit will come with a plot of irradiance non-uniformity. The working distance ranges for each simulator are listed in Table 3.

Sol3A Working Distances

Table 3 Working Distances

| Model | Size | Working Distance Range (Inches) |

|---|---|---|

| 94023A | 2 x 2 (50.8 x 50.8) | 12.0 ±0.5 |

| 94043A | 4 x 4 (101.6 x 101.6) | 4.0 ±0.5 |

| 94063A | 6 x 6 (152.4 x 152.4) | 5.0 ±0.5 |

| 94083A | 8 x 8 (203.2 x 203.2) | 15.0 ±0.5 |

| 94123A | 12x12 (304.8 x 304.8) |

手套箱

手套箱

薄膜制造

薄膜制造

真空镀膜

真空镀膜

电池设备

电池设备

实验室

实验室

联系我们

联系我们

京公网安备 11011402011250号

京公网安备 11011402011250号